Imagine the end of a long, busy production shift. Machines are humming, products are moving, and your team is ready to hand over the reins. But what if the next shift comes in with no clear picture of what just happened? Miscommunications can lead to missed targets, equipment breakdowns, and a general sense of chaos. It is a common challenge in many manufacturing environments, where the flow of information is as crucial as the flow of materials.

This is precisely where a well-structured production end of shift report template becomes an invaluable asset. It is not just about filling out a form; it is about creating a seamless bridge between shifts, ensuring that every piece of critical information is captured, communicated, and understood. Think of it as your daily operational diary, meticulously detailing the day’s successes, challenges, and everything in between, paving the way for the next team to hit the ground running.

In the following sections, we will delve into why such a template is essential for modern production facilities, what key elements should be included to make it truly effective, and how you can implement it to foster better communication and continuous improvement on your factory floor. Get ready to transform your shift handovers from a guessing game into a precise, strategic exchange.

Why a Solid Production End of Shift Report Template is Your Best Friend

Without a consistent method for recording shift details, critical information often falls through the cracks. Supervisors might rely on hurried verbal briefings, which are prone to misinterpretation or simply forgetting important points. This lack of structured data can lead to recurring problems, unnecessary downtime as the next shift tries to piece together the puzzle, and a general erosion of accountability. A robust production end of shift report template serves as a single source of truth, providing a comprehensive overview that leaves no room for ambiguity.

Beyond preventing miscommunication, a well-designed template offers a multitude of benefits. It helps in identifying trends, analyzing performance against targets, and proactively addressing potential issues before they escalate. It transforms anecdotal observations into actionable data, empowering management to make informed decisions about resource allocation, maintenance schedules, and process improvements. This systematic approach fosters a culture of transparency and continuous improvement across the entire production operation.

Key Information to Include in Your Report

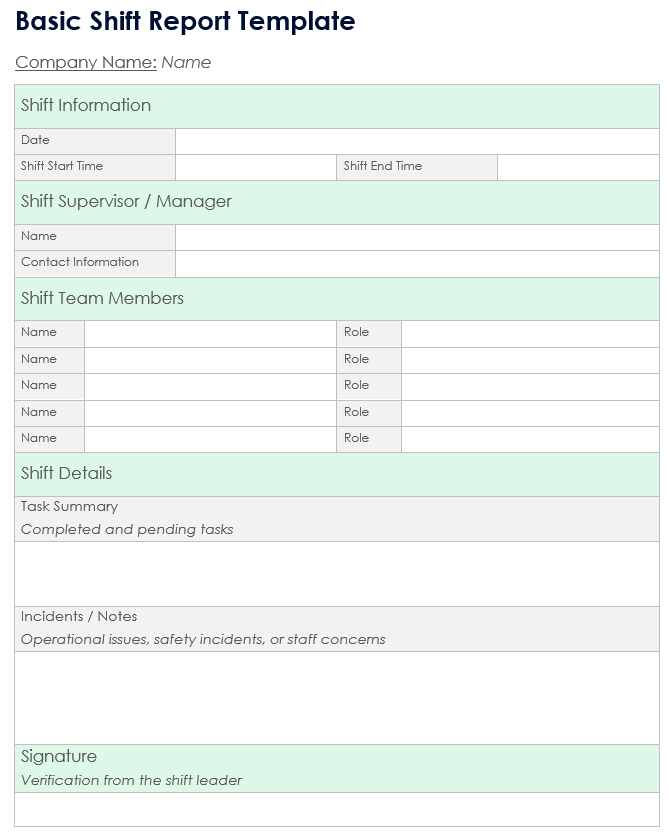

To truly be effective, your production end of shift report template needs to capture the essentials. It is not about overwhelming the team with paperwork, but about focusing on the data points that genuinely impact operations. Think about what the next shift needs to know immediately and what management needs for long-term analysis. Here is a breakdown of critical sections:

- Shift Identification: Date, start and end times of the shift, and the name of the shift supervisor or team lead. This establishes clear accountability and context.

- Production Overview: A summary of output for the shift. This includes units produced, planned targets versus actual achievement, and reasons for any significant deviations.

- Equipment Status: Details on the operational health of machinery. Report any downtime, breakdowns, maintenance performed, and any equipment needing attention in the next shift.

- Personnel Notes: Important staffing information such as absences, late arrivals, or any specific performance observations that need to be passed on.

- Safety and Quality Incidents: Document any near misses, accidents, safety hazards identified, quality control issues, defects, or reworks. This is vital for maintaining a safe and high-standard environment.

- Material Usage and Status: Note any material shortages, issues with raw materials, or specific material requirements for the upcoming shift.

- Open Items and Handover Notes: This section is crucial for continuity. List any tasks that are incomplete, problems that are still unresolved, or specific instructions for the next shift to follow up on.

Each of these items serves a unique purpose. Shift identification ensures traceability. Production figures drive performance analysis. Equipment status prevents unforeseen breakdowns. Safety and quality insights are non-negotiable for compliance and product integrity. Material details avert supply chain disruptions. And handover notes are the glue that holds the shifts together, preventing work from stalling or being duplicated.

Remember, the best production end of shift report template is one that is tailored to your specific operations. While the general categories remain consistent, the level of detail and specific metrics will vary based on your industry, machinery, and production processes. Regular review and adaptation of your template will ensure it remains relevant and maximally useful for your team.

Implementing Your Production End of Shift Report Template Effectively

Creating a fantastic production end of shift report template is only half the battle; successfully implementing it across your team is where the real magic happens. This process requires clear communication, training, and a willingness to adapt. Start by introducing the template during a team meeting, explaining its purpose and the benefits it brings, not just to management, but to the frontline workers themselves. Emphasize how it simplifies handovers, reduces stress, and improves overall efficiency.

Provide comprehensive training on how to accurately and thoroughly fill out each section. Consider a pilot phase where one or two shifts test the template and provide feedback before rolling it out company-wide. This allows for fine-tuning and addressing any initial challenges. Make the template easily accessible, whether through a digital system, a shared drive, or clearly designated physical binders. The easier it is for your team to use, the more consistently it will be adopted.

- Conduct thorough training: Explain the ‘why’ behind each section.

- Start with a pilot program: Gather feedback from early adopters.

- Ensure easy accessibility: Make the template readily available and user-friendly.

- Review and iterate: Periodically assess the template’s effectiveness and make necessary adjustments.

- Champion its use: Leaders should actively demonstrate and reinforce the importance of accurate reporting.

The long-term benefits of a diligently implemented template are immense. You will observe improved communication, fewer errors stemming from misinformation, and a clearer understanding of daily operations. This leads to more efficient problem-solving, better resource planning, and ultimately, a more productive and harmonious manufacturing environment for everyone involved.

Embracing a structured approach to shift handovers through a well-designed report template is a powerful step towards operational excellence. It transforms what could be a point of weakness into a pillar of strength, fostering continuity, accountability, and clarity across all shifts. This commitment to detailed, consistent communication empowers your team, streamlines processes, and paves the way for sustained improvement.

By investing time in developing and properly utilizing this critical tool, you are not just ticking a box; you are actively building a more resilient, efficient, and well-informed production facility. The ripple effect of better reporting touches every aspect of your operation, from employee morale to product quality and ultimately, your bottom line.