In the dynamic world of manufacturing, unexpected issues are almost a given. Whether it is a product defect, a process deviation, or an equipment malfunction, these hiccups can disrupt production, impact quality, and ultimately affect customer satisfaction and your bottom line. Simply identifying a problem isn’t enough; what truly matters is how effectively you address it and prevent its recurrence.

This is where a structured approach to problem-solving becomes invaluable. It moves beyond quick fixes, encouraging a deeper dive into the root causes of issues. By systematically analyzing what went wrong, you can implement changes that not only solve the immediate problem but also strengthen your entire operational framework, leading to more robust processes and higher quality outputs.

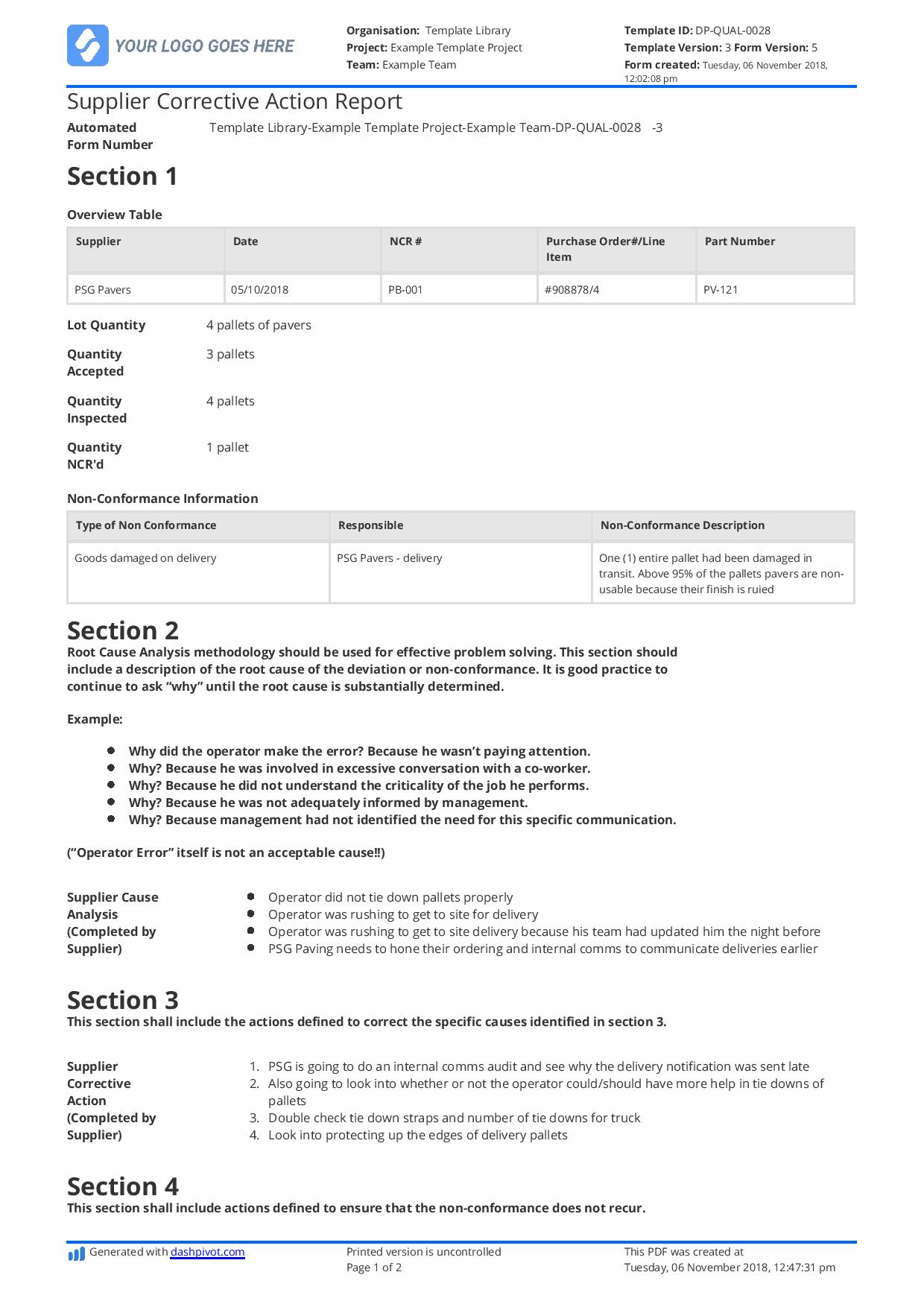

To streamline this critical process and ensure consistency, clarity, and accountability, a well-designed manufacturing corrective action report template is an indispensable tool. It provides a standardized framework for documenting problems, investigating their origins, detailing the actions taken, and verifying their effectiveness, turning every challenge into an opportunity for improvement.

The Anatomy of an Effective Corrective Action Report

A corrective action report (CAR) is far more than just a form; it is a vital communication and improvement tool designed to guide your team through the process of identifying, analyzing, and resolving non-conformities or deviations within your manufacturing operations. Its primary purpose is to ensure that problems are not only fixed but also that their underlying causes are eliminated, preventing future occurrences. Think of it as your roadmap to continuous improvement, helping you systematically turn setbacks into stepping stones for operational excellence.

When crafted properly, a CAR ensures that no stone is left unturned in the pursuit of resolving an issue. It forces a methodical approach, moving from the surface-level symptom to the core of the problem. This structured documentation is crucial not only for internal learning and process refinement but also for demonstrating compliance with various quality management standards like ISO 9001. A standardized manufacturing corrective action report template ensures everyone understands their role and responsibilities throughout the investigation and resolution process.

Essential Sections to Include

- Problem Description: Clearly state the non-conformity, what happened, when, where, and its impact.

- Containment Actions: What immediate steps were taken to mitigate the problem and prevent further spread?

- Root Cause Analysis: Delve into the “why” behind the problem using techniques like 5 Whys or Fishbone diagrams.

- Corrective Actions: Detail the specific actions taken to eliminate the root cause and prevent recurrence.

- Implementation Plan: Assign responsibilities, set deadlines, and outline resources needed for each corrective action.

- Verification of Effectiveness: How will you confirm that the corrective actions have worked and the problem is truly resolved?

- Preventive Actions (if applicable): Broader actions taken to prevent similar issues across different processes.

- Follow-up and Review: Schedule future checks to ensure sustained improvement.

- Approvals and Sign-offs: Ensure all relevant stakeholders have reviewed and approved the report.

Let’s delve a bit deeper into some of these crucial components. The “Problem Description” must be precise, factual, and devoid of blame. It sets the stage for the entire investigation. Following this, the “Root Cause Analysis” is arguably the most critical step. Without accurately identifying the root cause, any “corrective” action is merely a band-aid solution, destined to fail in the long run. This phase requires critical thinking, data analysis, and often, input from multiple team members.

Once the root cause is identified, the “Corrective Actions” section outlines the specific steps to be taken. These actions should directly address the root cause and be measurable, assignable, realistic, and time-bound. It’s not enough to say “improve training”; you need to specify “develop and implement a new training module for machine operators by [date], focusing on [specific skill].” Finally, the “Verification of Effectiveness” step closes the loop, ensuring that the implemented actions have truly solved the problem and that no new issues have been inadvertently created. This might involve monitoring process data, conducting audits, or re-inspecting products.

Implementing Your Corrective Action Process

Integrating a manufacturing corrective action report template seamlessly into your operational workflow is key to unlocking its full potential. It’s not just about having a form; it’s about embedding a culture of continuous improvement and proactive problem-solving. This means ensuring that every team member, from the shop floor to management, understands the purpose of the CAR and their role in its completion and follow-up. Training is paramount, focusing not only on how to fill out the template but also on the principles of root cause analysis and the importance of thorough documentation.

Effective implementation also involves assigning clear responsibilities. Who initiates a CAR? Who investigates the root cause? Who approves the corrective actions? Who verifies their effectiveness? Establishing these roles and responsibilities upfront prevents confusion and ensures accountability. Leveraging digital tools for your manufacturing corrective action report template can further streamline the process, allowing for easier tracking, collaboration, and data analysis, which can reveal recurring issues or areas needing systemic improvements.

Ultimately, the goal is to foster an environment where problems are seen not as failures, but as valuable learning opportunities. By consistently using a well-structured CAR process, your organization can move beyond reactive fire-fighting to a proactive stance, continuously refining processes, enhancing product quality, and building a more resilient and efficient manufacturing operation. This commitment to ongoing improvement through structured problem-solving is what truly differentiates high-performing companies.

Embracing a systematic approach to addressing non-conformities and implementing lasting solutions is fundamental to achieving sustained operational excellence. A robust corrective action process, anchored by a comprehensive template, empowers your team to not only resolve issues efficiently but also to extract valuable insights from every challenge. This transforms potential setbacks into powerful catalysts for growth and innovation.

By consistently applying the principles of problem description, root cause analysis, and verification of effectiveness, organizations can build a resilient framework that continually improves quality, reduces waste, and boosts overall productivity. Investing in the proper tools and training for your corrective action program is an investment in the long-term success and competitiveness of your manufacturing enterprise.