In the world of quality management, especially when striving for ISO 9001 certification or maintaining its standards, things don’t always go perfectly. Products might not meet specifications, services might fall short of expectations, or processes might deviate from established procedures. These are what we call non-conformances, and while they might sound like problems, they are actually invaluable opportunities for improvement if handled correctly.

Effectively addressing these deviations is critical for any organization committed to quality. It’s not enough to simply fix the immediate issue; you need a systematic way to understand what went wrong, why it happened, and how to prevent it from recurring. This is where a Non Conformance Report, often abbreviated as NCR, steps in. It’s your formal record of an issue, from its discovery to its resolution.

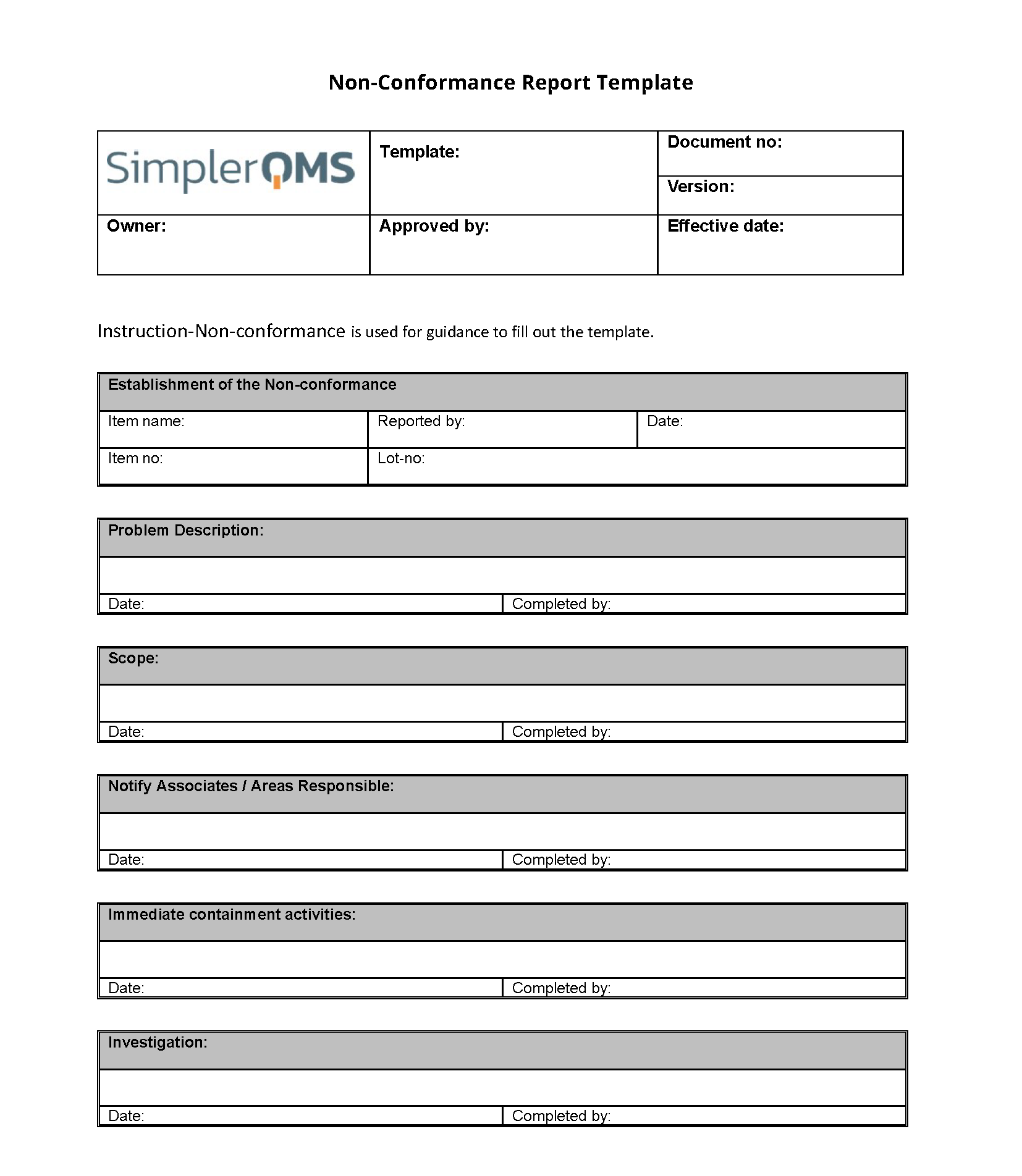

To ensure consistency, thoroughness, and compliance with ISO 9001 requirements, having a well-structured iso 9001 non conformance report template is absolutely essential. It provides a standardized framework that guides your team through the entire non-conformance management process, ensuring no critical step is missed and all necessary information is captured for analysis and improvement.Understanding the Core Components of an Effective Non Conformance Report

A non conformance report isn’t just a piece of paper; it’s a crucial tool in your quality management arsenal. Think of it as a detailed detective’s log for quality issues. When a product, service, or process doesn’t meet its specified requirements, an NCR is initiated to document the problem and drive it towards a resolution. For an NCR to be truly effective and compliant with ISO 9001, it needs to cover several key areas systematically.

At its heart, an NCR must clearly define the problem. This includes identifying what the non-conformance is, where it occurred, when it was detected, and who was involved or affected. Without these basic details, it’s impossible to properly investigate or resolve the issue. Let’s break down some of the vital sections you’d expect to find in a robust non conformance report template.

Details of the Non Conformance

This is where you paint a clear picture of the problem. You need to be specific and factual, avoiding assumptions or blame. Document the exact nature of the non-conformance, including any relevant product identification numbers, batch numbers, or service codes. Mention the date and time of discovery, the location where it was found (e.g., production line, customer site, during inspection), and who reported it. It’s also vital to reference the specific requirement that was not met, whether it’s an internal procedure, a customer specification, or an ISO 9001 clause.

Think about the “5 W’s and 1 H” approach: What happened? When did it happen? Where did it happen? Who was involved? Why is it a non-conformance? And How was it identified? Providing objective evidence, such as photos, measurements, or witness statements, can significantly strengthen this section.

Investigation and Root Cause Analysis

Finding the root cause is perhaps the most critical step. It’s easy to just fix the symptom, but if you don’t address the underlying cause, the non-conformance is likely to recur. This section of your template should prompt a thorough investigation into why the non-conformance occurred. Was it a human error? Equipment malfunction? A flawed process? Insufficient training? External factors?

Common techniques for root cause analysis, like the “5 Whys” (asking “why?” five times until the fundamental cause is uncovered) or Fishbone diagrams, can be incredibly helpful here. Documenting the investigation process and the identified root cause is paramount for demonstrating compliance and fostering continuous improvement.

Containment and Corrective Actions

Once the non-conformance is identified and its root cause determined, you need to act. This section typically has two parts: containment actions and corrective actions. Containment actions are immediate steps taken to mitigate the impact of the non-conformance, prevent further issues, and protect customers. For instance, quarantining affected products or stopping a faulty process.

Corrective actions, on the other hand, are the long-term solutions designed to eliminate the root cause and prevent recurrence. These should be clearly defined, assigned to specific individuals, and given realistic deadlines. After implementation, it’s crucial to verify their effectiveness to ensure the problem truly won’t happen again. The template should also include a section for follow-up and verification of these actions. Here are some examples:

- Immediate product recall or quarantine to prevent customer impact

- Re-training staff members on a specific procedure

- Updating process documentation or work instructions

- Modifying equipment or software settings

Finally, your iso 9001 non conformance report template should include sections for review and closure. This ensures that the non-conformance has been fully addressed, the corrective actions have been verified as effective, and all necessary documentation is complete. It often involves sign-offs from relevant personnel, including quality managers, confirming the issue is resolved and closed.

Why a Standardized Iso 9001 Non Conformance Report Template is Your Best Friend

Implementing a standardized iso 9001 non conformance report template brings a multitude of benefits to any organization serious about quality management. Firstly, it ensures consistency across all departments and individuals. Everyone follows the same process, captures the same essential information, and communicates in a uniform manner, which drastically reduces ambiguity and misunderstandings during critical situations.

Secondly, a template streamlines the entire non-conformance management process. It acts as a clear checklist, guiding users step-by-step from detection to resolution. This not only makes the process more efficient but also reduces the likelihood of crucial information being overlooked or vital steps being skipped. New employees can be trained more quickly on how to handle non-conformances, and even seasoned staff benefit from the clarity it provides, especially under pressure.

Ultimately, a robust template serves as invaluable evidence during ISO 9001 audits, demonstrating your organization’s commitment to quality, its systematic approach to addressing issues, and its dedication to continuous improvement. It transforms potential pitfalls into structured learning opportunities, strengthening your quality management system with every non-conformance resolved. Here are some key advantages:

- Ensures all critical information is captured consistently for every incident

- Simplifies training for new employees on non-conformance procedures

- Accelerates the non-conformance resolution process by providing clear steps

- Provides clear, structured data for management review and trend analysis

- Helps demonstrate clear compliance during external ISO 9001 audits

Embracing a systematic approach to handling non-conformances, supported by a well-designed template, transforms potential weaknesses into powerful drivers for continuous improvement. It fosters a culture of learning and accountability, where every deviation from the norm becomes an opportunity to refine processes, enhance products, and ultimately deliver greater value to your customers.

By making the non-conformance process clear, consistent, and actionable, organizations can not only maintain their ISO 9001 certification but also build a truly resilient and high-performing quality management system that stands the test of time.