In the bustling world of manufacturing, where every minute counts and precision is paramount, the smooth transition between shifts is an often-underestimated cornerstone of operational efficiency. Imagine a busy factory floor, machines humming, products moving along the line, and then suddenly, one shift ends and another begins. Without a clear, comprehensive handover, vital information can easily slip through the cracks, leading to costly delays, errors, or even safety concerns. This daily ritual, if not managed correctly, can create a ripple effect that impacts production schedules, quality control, and overall team morale.

This is precisely where a standardized approach becomes invaluable. A well-designed system ensures that all critical details from the outgoing team are accurately and consistently communicated to the incoming crew. It bridges the gap between different teams, making sure everyone is on the same page regarding production targets, machine status, any issues encountered, and priorities for the next shift. It transforms a potentially chaotic moment into a structured and productive exchange of information.

The right tool can make all the difference in achieving this seamless transition. By adopting a dedicated framework, manufacturing facilities can significantly enhance their internal communication and operational continuity. This article explores the benefits and essential components of a robust reporting system, guiding you through how a strategic framework can elevate your factory’s performance and ensure nothing is left to chance during those critical shift changes.

The Indispensable Role of a Structured Shift Report

Picture this: the night shift is wrapping up, and the day shift is about to clock in. Without a standardized system, the outgoing supervisor might verbally pass on a few key points, while the incoming one tries to scribble them down on a notepad. Important nuances might be missed, critical machine issues could be forgotten, or quality concerns might not be fully conveyed. This informal approach is a recipe for inconsistency and potential problems down the line. A structured shift report, however, eliminates this guesswork and provides a consistent, reliable record of everything that happened and needs attention. It serves as a single source of truth, ensuring that every piece of information, no matter how small, is documented and accessible.

Such a report becomes a vital communication bridge, not just between shifts but also for management to gain an overview of daily operations. It allows for quick identification of recurring problems, helps in tracking performance metrics over time, and supports data-driven decision making. When everyone knows exactly what information needs to be captured and where, the handover process becomes efficient and transparent, fostering accountability among all team members. It’s about creating a culture where information sharing is not just encouraged but systematized, reducing the chances of miscommunication and boosting overall productivity.

One of the most powerful aspects of a detailed report is its ability to highlight anomalies and trends that might otherwise go unnoticed. For instance, if a particular machine experiences frequent minor breakdowns reported across several shifts, the consistent documentation will quickly flag it as a maintenance priority, preventing a major, more costly failure later on. This proactive approach to problem-solving is a direct benefit of having a well-defined reporting structure. It allows for continuous improvement by providing concrete data points for analysis and action.

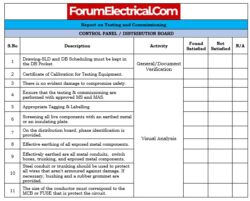

Key Elements to Include in Your Manufacturing End of Shift Report Template

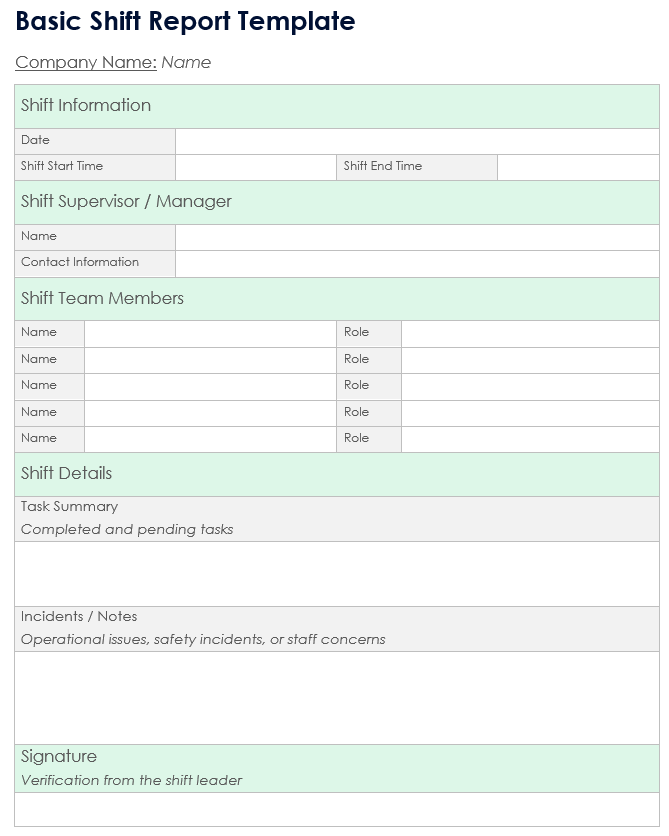

To be truly effective, a manufacturing end of shift report template should capture a comprehensive range of information. It should be designed to be easy to fill out yet thorough enough to cover all critical aspects of the shift’s operations. The exact details might vary slightly depending on your specific industry or production process, but some core elements are universally beneficial.

Consider including these critical sections to ensure your template is robust and informative:

- Shift Identification: Date, shift number (e.g., first, second, third), and the names or IDs of the supervisor and team members for both outgoing and incoming shifts.

- Production Summary: Total units produced, target units, variance, and any specific product types or batches completed.

- Machine Status and Downtime: A list of all operational machines, any machines that experienced issues or downtime (including start and end times, reasons for downtime, and actions taken).

- Quality Control Notes: Any quality issues identified, rejected products, rework required, or specific quality checks performed and their results.

- Safety Incidents: Details of any accidents, near misses, or safety concerns reported during the shift.

- Maintenance Requirements: New maintenance requests, follow-ups on previous requests, or any observations of equipment needing attention.

- Material and Inventory Updates: Shortages, surpluses, or specific material movements that impact the next shift.

- Personnel Notes: Call-outs, absences, or specific performance observations relevant to team dynamics or training needs.

- Special Instructions/Priorities for Next Shift: Any urgent tasks, specific production changes, or critical follow-ups required by the incoming team.

- Supervisor Comments: An open section for any additional notes, observations, or general overview.

This detailed capture ensures that the manufacturing end of shift report template provides a holistic view of the shift’s activities and sets the next team up for success by clearly outlining priorities and potential challenges.

Customizing and Implementing Your Reporting System

While a generic manufacturing end of shift report template provides an excellent starting point, its true power lies in its ability to be customized to your specific operational environment. Every factory is unique, with its own machinery, production processes, and reporting needs. Therefore, taking the time to tailor the template to reflect your distinct workflows, terminology, and key performance indicators will significantly increase its relevance and adoption rate among your teams. Involve your supervisors and frontline workers in the customization process; they are the ones who will be using it daily and can offer invaluable insights into what information is most critical for a smooth handover and effective operation.

Once you have a refined template, successful implementation requires more than just handing it out. It necessitates clear communication, comprehensive training, and consistent enforcement. Educate your teams on the “why” behind the report—how it benefits them by reducing confusion, improving safety, and making their jobs easier. Provide thorough training on how to accurately and efficiently fill out each section, emphasizing the importance of detail and objectivity. Regularly review submitted reports for completeness and accuracy, offering constructive feedback to ensure everyone understands the expectations. This iterative process of training and feedback will solidify the reporting practice within your organizational culture.

The advantages of a well-implemented reporting system extend far beyond just better handovers. Over time, the accumulated data from these reports can become a treasure trove for operational analysis. You can identify patterns in machine breakdowns, pinpoint recurring quality issues, track individual and team performance, and make informed decisions about resource allocation or process improvements. This robust data empowers management to optimize production, reduce waste, and ultimately enhance the factory’s overall efficiency and profitability. It transforms anecdotal observations into concrete, actionable insights, driving continuous improvement across the board.

Embracing a systematic approach to shift reporting is not just about filling out forms; it is about building a foundation of transparency, accountability, and continuous improvement within your manufacturing operations. By providing a clear, consistent means for information exchange, you empower your teams to operate more effectively, minimize disruptions, and collectively work towards higher productivity and quality standards. This strategic investment in communication will undoubtedly yield substantial returns, fostering a more organized, efficient, and resilient manufacturing environment for years to come.