Ensuring the quality and accuracy of goods before they leave the factory is a critical step in international trade. It’s not just about meeting customer expectations; it’s about safeguarding your brand reputation and avoiding costly disputes down the line. A thorough pre-shipment inspection acts as your final gatekeeper, a crucial checkpoint that can catch errors before they become major headaches.

However, conducting an inspection is only half the battle. Documenting the findings clearly, comprehensively, and consistently is equally important. Without a structured approach, valuable information can be lost, misunderstood, or become difficult to retrieve when needed most. This is where a standardized reporting system becomes invaluable, transforming raw data into actionable insights.

Imagine having a ready-to-use framework that guides your inspectors, captures all essential details, and presents the results in an easy-to-understand format. That’s the power of a well-designed pre shipment inspection report template. It streamlines the process, ensures uniformity across all inspections, and provides a clear record for all stakeholders, from manufacturers to final customers.

What Goes Into a Comprehensive Pre Shipment Inspection Report?

When you’re dealing with products ready to embark on a long journey, leaving no stone unturned during the inspection is paramount. A truly comprehensive pre shipment inspection report template isn’t just a simple checklist; it’s a detailed narrative of the product’s condition and compliance at a specific point in time. It needs to cover everything from the basic order details to the nitty-gritty of quality checks and packaging integrity, providing a complete picture for anyone reviewing the document.

The report should start by setting the scene, outlining exactly who, what, and where the inspection took place. This foundational information ensures that the report is easily identifiable and provides context for the findings that follow. It’s like the opening chapter of a book, giving you all the necessary background before diving into the main story of the inspection.

Inspection Details

This section is all about the administrative information that anchors the report to a specific event and order. Accuracy here is crucial for record-keeping and traceability.

- Date and Time of Inspection

- Name(s) of Inspector(s)

- Client Company Name

- Supplier/Factory Name and Location

- Purchase Order (PO) Number

- Product Name and Item Code

- Quantity Ordered

Quantity and Packaging Verification

Once the basic details are covered, the report moves into the physical aspects of the shipment. This involves confirming that the correct number of items are present and that they are adequately prepared for transit. Improper packaging can lead to damage, regardless of how perfect the product was initially.

- Total Quantity Inspected

- Number of Cartons/Pallets

- Verification of Packaging Materials (e.g., strong cartons, appropriate inner packing)

- Accuracy of Shipping Marks and Labels (e.g., PO number, product name, quantity)

- Condition of Outer Packaging (e.g., no damage, clean, dry)

Product Specification and Quality Checks

This is arguably the heart of the pre-shipment inspection. Here, the products are rigorously checked against the agreed-upon specifications, approved samples, and quality standards. This can involve a range of tests, from visual examinations to functional performance checks, all aimed at identifying any deviations before shipment.

- Visual Inspection for Defects (e.g., scratches, dents, incorrect colors, poor finishing)

- Dimensional and Weight Verification against specifications

- Material Composition Check (if applicable, e.g., fabric type, metal grade)

- Functional Testing (e.g., power on/off, all features working, safety mechanisms)

- Safety and Regulatory Standard Compliance Check

- Workmanship Quality Assessment

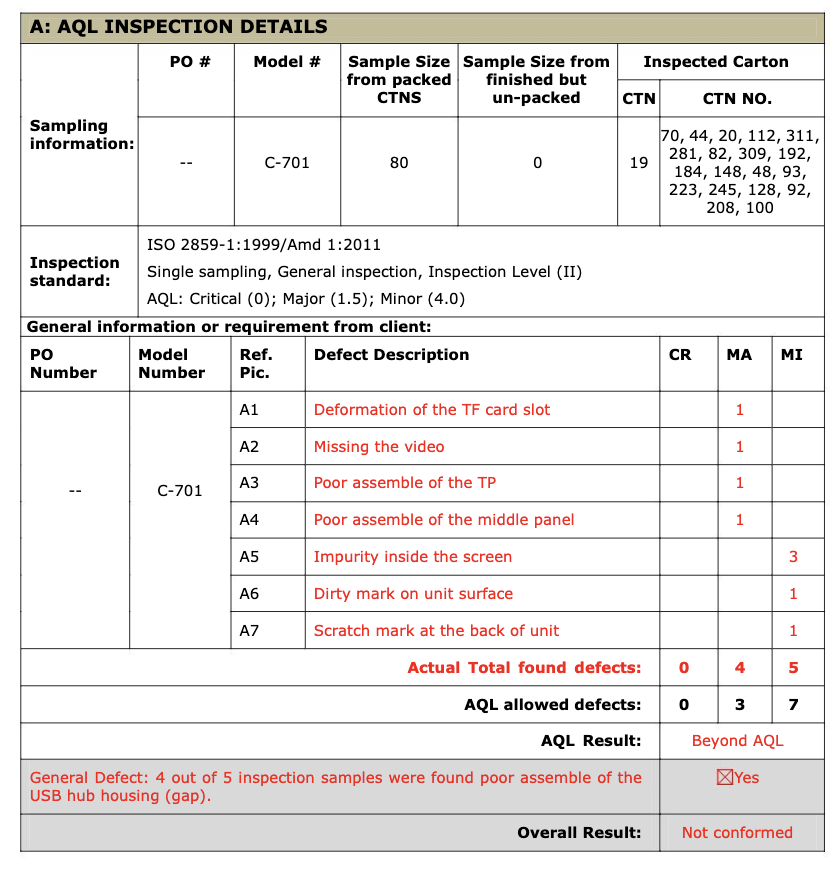

Defect Classification and AQL Sampling

A good report will also categorize any identified defects, typically into critical, major, and minor. This helps in understanding the severity of the issues found. The report should also clearly state the Acceptance Quality Limit (AQL) used for sampling and the outcome of that sampling.

Overall Findings and Recommendations

Finally, the report culminates in a summary of the findings, including the overall pass/fail status of the inspection. This section provides a concise overview and offers clear recommendations for the next steps, whether it’s approving shipment, holding for rework, or reinspection. Clear photos of any issues found are invaluable here.

Choosing the Right Pre Shipment Inspection Report Template for Your Business

Selecting the perfect pre shipment inspection report template isn’t a one-size-fits-all endeavor. Different industries, product types, and company sizes will have varying needs and priorities when it comes to documenting their quality control processes. What works for a textile manufacturer might be entirely insufficient for an electronics firm, and vice versa. It’s about finding a template that not only captures the necessary data but also aligns seamlessly with your operational workflow and quality standards.

Consider the level of detail required for your specific products. Are you inspecting highly complex machinery where extensive functional testing data is crucial, or simpler consumer goods where visual aesthetics and quantity are the primary concerns? The template should be flexible enough to accommodate these nuances, perhaps with customizable fields or optional sections that can be toggled on or off as needed. Digital templates often offer this level of adaptability, allowing for easier modification and sharing.

A well-chosen template will not only simplify the inspection process but also enhance the consistency and reliability of your quality control efforts. It becomes a valuable tool for communicating expectations to suppliers, providing objective evidence for stakeholders, and ultimately, building a robust quality assurance system that protects your investments and upholds your brand’s reputation.

A robust pre shipment inspection report template is more than just a document; it’s a strategic asset in your supply chain management toolkit. It standardizes your quality control efforts, provides clear communication channels, and creates an immutable record of product quality before goods leave the factory floor. This proactive approach minimizes risks, reduces costly returns and rework, and builds a stronger foundation of trust with your international partners and customers.

By investing time in developing or selecting the right template, you empower your inspection team to perform their duties with greater efficiency and accuracy. The comprehensive data captured becomes a valuable resource for continuous improvement, helping you identify recurring issues, refine product specifications, and strengthen your overall quality assurance strategy for future orders.