In today’s fast-paced business world, maintaining high-quality standards is not just a goal, it’s a necessity. From the raw materials that arrive at your factory floor to the finished products shipped to customers, every link in the supply chain plays a critical role. But what happens when things don’t go as planned? When a supplier delivers a batch of non-conforming parts or provides a service that falls short of expectations, it can disrupt operations, impact customer satisfaction, and even lead to significant financial losses.

Addressing these issues effectively and systematically is paramount. Simply returning defective goods or voicing a complaint might solve the immediate problem, but it rarely prevents recurrence. To truly drive continuous improvement and foster stronger, more reliable supplier relationships, a structured approach is required. This is where a formal process for documenting, analyzing, and resolving non-conformances with your suppliers comes into play.

Having a clear, consistent method for communication and problem-solving can transform a frustrating setback into an opportunity for growth and enhanced quality across your entire value chain. That’s why many organizations turn to a specialized tool designed to streamline this crucial process, ensuring that every issue is meticulously tracked from identification to resolution.

Understanding the SCAR Process: Why It’s Crucial for Quality Assurance

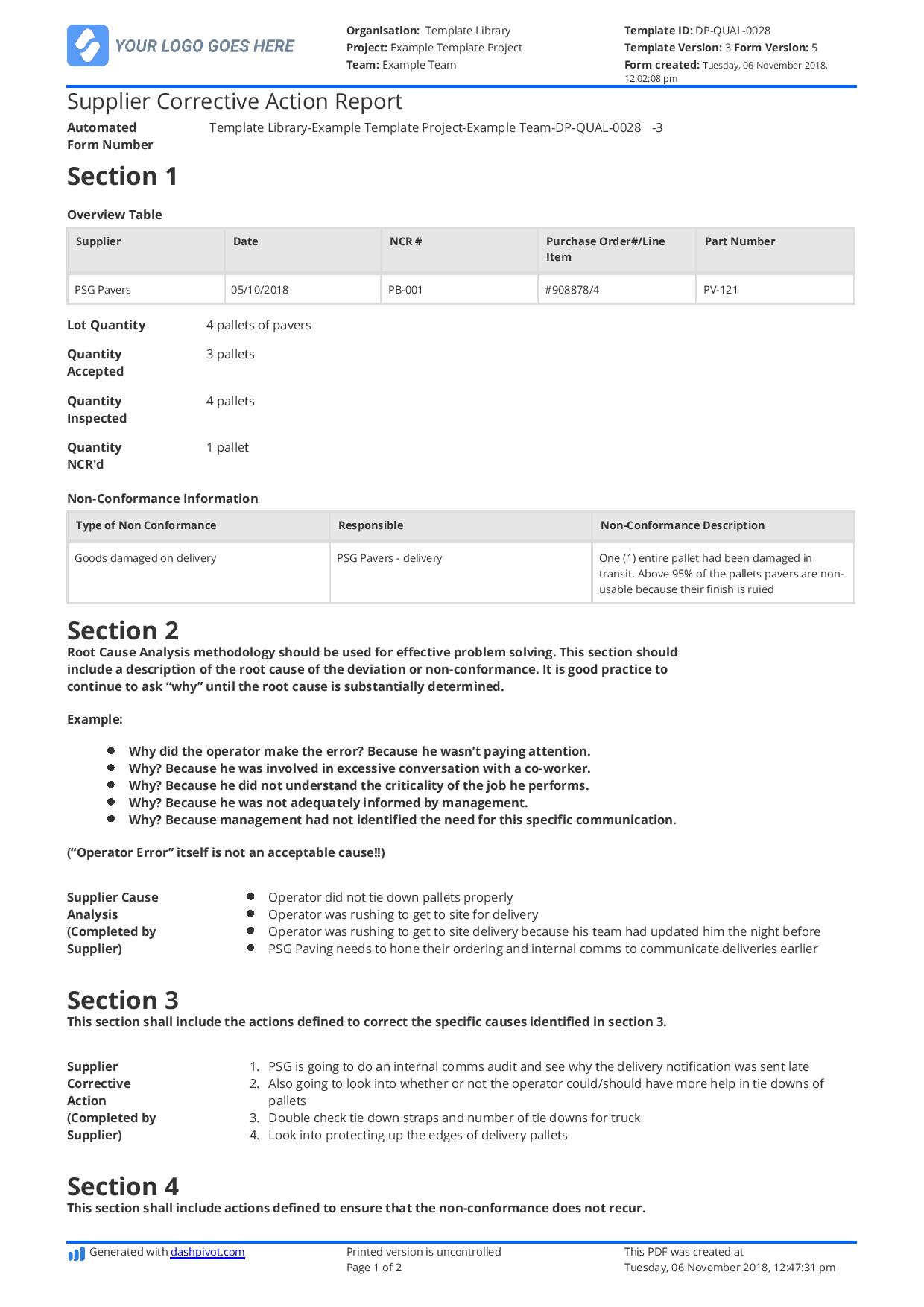

A Supplier Corrective Action Report (SCAR) is more than just a form; it’s a communication tool and a structured methodology used to formally request a supplier to investigate and resolve non-conformance issues. When an issue arises with a supplied product or service, your organization initiates a SCAR, detailing the problem and requesting the supplier to identify its root cause, implement corrective actions, and provide evidence of effectiveness. This process is fundamental for maintaining quality control and fostering a culture of continuous improvement within your supply chain.

The benefits of implementing a robust SCAR process are multifaceted. It ensures that problems are not just superficially patched, but fundamentally addressed at their source. This systematic approach leads to increased product quality, reduced waste, improved efficiency, and ultimately, stronger, more reliable partnerships with your suppliers. It shifts the dynamic from blame to collaboration, focusing on finding solutions and preventing future occurrences. Without a standardized approach, tracking progress, holding parties accountable, and verifying the effectiveness of changes can become an impossible task, leading to recurring issues and a decline in overall quality.

Imagine the frustration of receiving the same defective component repeatedly. A SCAR breaks this cycle by demanding a structured response. It typically involves several stages: initial notification of the non-conformance, the supplier’s root cause analysis, the proposal and implementation of corrective actions, and finally, your organization’s verification that the actions have been effective in preventing recurrence. Each step is critical, requiring clear documentation and communication to ensure a successful resolution.

Key Components of an Effective Supplier Corrective Action Report Template

To ensure your SCAR process is efficient and effective, utilizing a comprehensive supplier corrective action report template is invaluable. A well-designed template guides both you and your supplier through the necessary steps, ensuring all critical information is captured and nothing is overlooked. It standardizes the reporting process, making it easier to track, analyze, and communicate.

Here are the essential components you should look for in a robust template:

- SCAR Number and Date: For easy tracking and reference.

- Supplier Information: Full details of the supplier involved.

- Originator Information: Details of the person initiating the SCAR.

- Non-conformance Description: A clear, concise, and objective description of the problem, including relevant dates, quantities, and supporting evidence (photos, specifications, test reports).

- Root Cause Analysis: Space for the supplier to document their investigation into the underlying causes of the non-conformance. This is crucial for preventing recurrence.

- Corrective Actions: Details of the immediate actions taken to contain the problem and the systemic actions implemented to prevent it from happening again. This often includes both short-term containment and long-term preventative measures.

- Implementation Date and Verification: Dates for when actions were implemented and space for your team to verify their effectiveness.

- Signatures and Approval: Spaces for both supplier and customer approval, indicating agreement and closure.

By ensuring these components are consistently addressed, a well-structured template not only facilitates problem resolution but also serves as a valuable record for auditing, performance reviews, and future supplier selection decisions. It fosters transparency and accountability, turning potential friction points into opportunities for mutual improvement.

Implementing and Maximizing Your Supplier Corrective Action Report Template

Successfully integrating a SCAR process into your quality management system requires more than just having a good template; it demands clear communication, consistent application, and a commitment from both parties. Start by clearly defining when a SCAR should be issued and ensure all relevant personnel are trained on how to properly complete and submit the template. Establishing a clear channel for communication with your suppliers regarding the SCAR process will minimize delays and misunderstandings, fostering a collaborative environment aimed at solving problems rather than assigning blame.

It’s also crucial to avoid common pitfalls that can undermine the effectiveness of your SCAR efforts. These include providing insufficient details in the non-conformance description, which can lead to misinterpretation and incorrect root cause analysis by the supplier. Another frequent issue is a lack of diligent follow-up and verification once corrective actions are reported. Without proper checking, there’s no guarantee that the problem has truly been solved and won’t reappear. Remember, the goal is not just to close a SCAR, but to ensure that the issue is permanently resolved and that quality improvements are sustained.

Ultimately, leveraging your SCAR template effectively goes beyond fixing immediate issues; it’s about building a more resilient and reliable supply chain. By consistently applying the process, you create a historical record of supplier performance, which can inform future purchasing decisions and provide valuable data for your own internal quality initiatives. This proactive approach strengthens relationships, reduces risks, and contributes significantly to your organization’s overall success and reputation for quality.

Maintaining robust quality across your supply chain is a continuous journey, not a destination. A well-designed and consistently utilized tool for managing non-conformances acts as a cornerstone of this journey, ensuring that every deviation from quality standards is systematically addressed. It transforms potential setbacks into opportunities for learning and improvement, benefiting both your organization and your valuable supplier partners.

Embracing a structured methodology for addressing supplier issues streamlines operations, minimizes disruptions, and drives higher levels of product and service quality. By proactively engaging with your suppliers through a clear and comprehensive process, you foster transparency, accountability, and a shared commitment to excellence. Having a readily available, easy-to-use supplier corrective action report template is an indispensable asset for any organization dedicated to achieving and maintaining superior quality standards.