Ensuring the quality of your products or services often hinges on the reliability of your suppliers. A robust supply chain is the backbone of any successful business, and a crucial component of maintaining that strength is through regular, thorough supplier quality audits. But what happens after the audit? How do you document your findings, track progress, and communicate vital information effectively? This is where a well-structured supplier quality audit report template becomes an indispensable tool.

Think of it this way: without a clear, consistent way to record your audit results, you risk losing valuable insights, misinterpreting data, and struggling to implement necessary improvements. A standardized template doesn’t just make your life easier; it provides a professional framework for documenting everything from initial observations to corrective actions, ensuring nothing falls through the cracks. It transforms raw data into actionable intelligence, driving continuous improvement within your supplier relationships.

Whether you’re new to supplier auditing or looking to refine your current process, understanding the components of an effective report template can significantly elevate your quality management efforts. It’s about more than just checking boxes; it’s about fostering transparency, accountability, and a shared commitment to quality across your entire supply network. Let’s dive into what makes an excellent template and how it can empower your quality team.

Crafting a Comprehensive Supplier Quality Audit Report

A truly effective supplier quality audit report is more than just a summary of what you found. It’s a detailed, actionable document that serves multiple purposes: it informs, guides, and provides a historical record for future reference. Without a clear structure, audits can become disjointed, making it difficult to compare results over time or ensure that corrective actions are actually implemented and effective. This is where the power of a standardized template truly shines, offering a consistent framework that ensures all critical information is captured systematically.

When you’re putting together or utilizing a supplier quality audit report template, you want to ensure it covers all the bases, from the logistical details of the audit itself to the intricate findings and proposed remedies. The goal isn’t just to identify problems, but to provide a pathway to resolution and improvement. A well-designed template guides the auditor through each step, prompting them to collect specific types of information and present it in an easily understandable format. This consistency is vital for internal review, communication with the supplier, and potential regulatory compliance.

One of the primary advantages of using a template is the standardization it brings. Imagine trying to compare audit results from different auditors using wildly different reporting styles. It would be a nightmare. A template ensures that every report, regardless of who conducted the audit, presents information in a predictable manner, making comparisons, trend analysis, and decision-making far more straightforward. It reduces ambiguity and enhances clarity, which is crucial when discussing sensitive findings with suppliers or internal stakeholders.

Moreover, a robust template encourages thoroughness. By including dedicated sections for various aspects of the audit, it prompts auditors to consider all areas, from facility conditions to documentation practices. This structured approach minimizes the chances of overlooking critical details that could have significant implications for product quality or regulatory adherence. It essentially acts as a checklist for the reporting phase, ensuring that every significant observation is documented appropriately and followed up on.

Key Sections to Include in Your Template

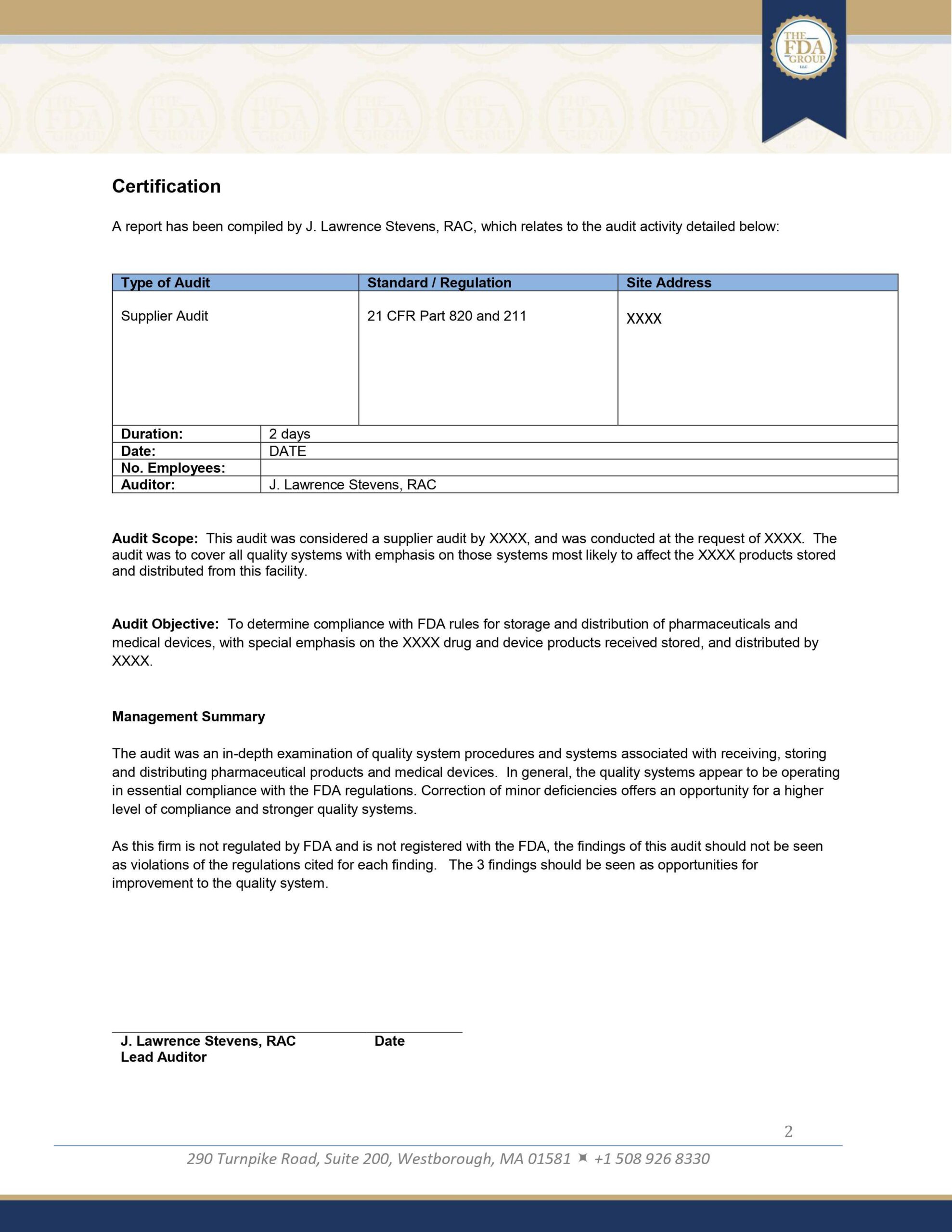

- Audit Details: Basic information like audit date, auditor(s) names, supplier name and contact, audit type (e.g., initial, surveillance, re-audit).

- Executive Summary: A concise overview of the audit’s scope, key findings, and overall conclusion, ideal for busy executives.

- Audit Scope and Objectives: Clearly define what was audited and the purpose of the audit.

- Methodology: Describe the approach taken during the audit, including any standards referenced (e.g., ISO 9001).

- Findings: This is the core. Detail non-conformances (major/minor), observations, and positive findings/strengths. Each finding should include evidence, the requirement it violates (if applicable), and its potential impact.

- Corrective and Preventive Actions (CAPA) Request: A section for outlining required actions, deadlines, and responsibilities for the supplier to address non-conformances.

- Recommendations: Suggestions for improvement that aren’t necessarily non-conformances but could enhance quality or efficiency.

- Conclusion and Overall Rating: A summary of the supplier’s quality system effectiveness and an overall assessment.

- Signatures and Approvals: Spaces for the auditor, supplier representative, and management to sign off, indicating agreement or acknowledgment of the report.

The Tangible Benefits of a Standardized Report

Implementing a standardized supplier quality audit report template across your organization brings a host of tangible benefits that extend beyond mere documentation. Firstly, it significantly enhances efficiency. Auditors spend less time figuring out how to structure their reports and more time focusing on the actual audit findings. This streamlined process means faster report generation, quicker dissemination of information, and ultimately, a more agile response to potential quality issues. Time saved in reporting translates directly into more time for proactive quality management initiatives.

Secondly, a template fosters unparalleled consistency and comparability. When all audit reports follow the same format, it becomes incredibly easy to compare a supplier’s performance over time or to benchmark different suppliers against each other. This consistency is invaluable for trend analysis, allowing you to identify recurring issues, track the effectiveness of corrective actions, and make data-driven decisions about your supplier relationships. It provides a clear, objective record that supports strategic sourcing and supplier development efforts.

Finally, a well-defined template acts as a powerful communication tool. It ensures that critical information is presented clearly and unambiguously to all stakeholders, from the supplier being audited to internal management and even regulatory bodies. This clarity minimizes misunderstandings, facilitates constructive dialogue, and strengthens collaborative efforts to improve quality. It lends credibility to your audit process and reinforces your commitment to maintaining high-quality standards throughout your supply chain, ultimately safeguarding your brand’s reputation and customer satisfaction.

Adopting a structured approach to documenting your supplier quality audits is more than just good practice; it’s a strategic imperative for any business serious about maintaining high standards. A robust reporting system empowers your team to not only identify issues but also to drive meaningful, measurable improvements within your supply chain. It transforms the audit from a one-off event into a continuous cycle of assessment, feedback, and enhancement.

By consistently using a comprehensive supplier quality audit report template, you’re investing in clearer communication, stronger supplier relationships, and ultimately, a more reliable and resilient product or service offering. It’s a foundational element in building a truly world-class quality management system, ensuring that quality isn’t just a goal, but a consistent reality from the very first link in your supply chain.