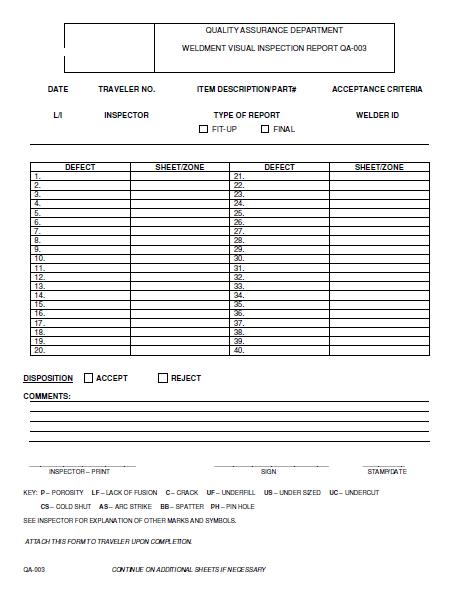

In the world of fabrication, construction, and manufacturing, the integrity of welded joints is paramount. It’s not just about strength; it’s about safety, reliability, and ultimately, the success of an entire project. Before any other non-destructive testing, visual inspection stands as the foundational step, catching many potential issues early on. This initial check is crucial for ensuring that welds meet specified quality standards and for preventing costly rework or catastrophic failures down the line.

However, conducting thorough visual inspections is only half the battle. Documenting these inspections effectively is where many operations fall short. Without a consistent method, critical information can be missed, communication between teams can become muddled, and proving compliance with industry standards becomes a challenging task. This is where the right tools, like a structured reporting system, become indispensable.

Imagine a scenario where every inspection, regardless of the inspector or the project, follows the same comprehensive checklist, captures all necessary details, and provides clear, actionable insights. This level of consistency and clarity is not a luxury; it’s a necessity. Utilizing a well-designed visual welding inspection report template transforms a potentially haphazard process into a systematic, reliable, and auditable procedure, ensuring nothing is overlooked and quality is maintained.

Why a Standardized Visual Welding Inspection Report is Crucial

Having a standardized approach to visual welding inspection reporting isn’t just about ticking boxes; it’s a fundamental aspect of quality assurance and risk management in any industry that relies on welded structures. Without it, you’re essentially leaving critical data collection to chance, which can have significant repercussions for safety, project timelines, and your bottom line. A consistent template ensures that every inspector, from the seasoned veteran to the newer team member, collects the same essential data points, fostering uniformity across all projects.

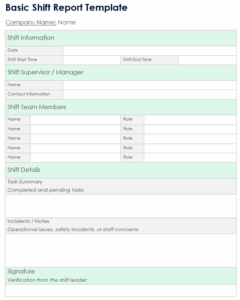

One of the primary benefits is the undeniable boost in consistency. Imagine a large project with multiple inspectors working across different shifts or locations. If each inspector uses their own method of documentation, the reports will inevitably vary in content, detail, and clarity. A standardized visual welding inspection report template acts as a unifying framework, dictating what information must be captured, how it should be presented, and what criteria are being used for acceptance or rejection. This eliminates ambiguity and ensures that all stakeholders are looking at comparable data.

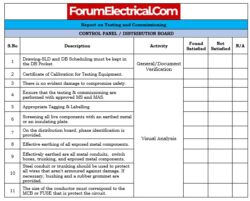

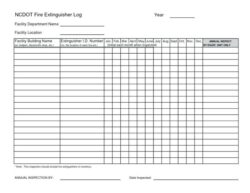

Beyond consistency, a robust template significantly enhances traceability and compliance. In many industries, adherence to specific codes and standards (such as AWS D1.1, ASME Section IX, or API 1104) is not just good practice but a legal requirement. A well-documented report serves as irrefutable evidence that inspections were performed according to these standards, providing a clear audit trail. Should any issues arise later, these reports are invaluable for forensic analysis, identifying root causes, and demonstrating due diligence.

Furthermore, clear documentation facilitates better communication. When a weld is deemed unacceptable, the report needs to articulate precisely why, what the defect is, and where it’s located. This clear feedback allows welders to understand their errors, learn from them, and make precise corrective actions. Project managers can use the aggregated data to track overall quality trends, identify recurring issues, and make informed decisions about process improvements or welder training needs. This feedback loop is essential for continuous improvement.

Ultimately, a structured reporting system minimizes costly mistakes. Catching discontinuities like porosity, undercut, or cracks visually and documenting them accurately before further work proceeds saves immense amounts of time and money that would otherwise be spent on rework, repairs, or even complete structural failures. It’s a proactive step that pays dividends in long-term operational efficiency and reputation.

Key Elements to Include in Your Template

- Project and General Information: Date of inspection, project name and number, client name, inspector’s name and qualification ID, location of the inspection.

- Weld Identification: Unique weld number, drawing reference, joint type, material specifications (base metal and filler metal), welding process used (e.g., SMAW, GMAW, GTAW).

- Visual Inspection Criteria: Reference to applicable codes, standards, or specifications for acceptance and rejection.

- Observed Discontinuities: A comprehensive list of common weld defects (e.g., porosity, undercut, overlap, incomplete fusion, cracks, excessive reinforcement, spatter) with space to describe their location, size, and severity.

- Acceptance/Rejection Status: Clear indication of whether the weld passed or failed the visual inspection.

- Corrective Actions/Recommendations: Space to detail any required repairs, re-inspections, or recommendations for improvement.

- Photographic Evidence: A section to note if photographs were taken and where they are stored.

- Signature and Approval: Signatures of the inspector, and if applicable, a witness or project manager for final approval.

- Notes/Comments: An open section for any additional observations or relevant information.

Implementing and Maximizing Your Visual Welding Inspection Report Template

Once you’ve decided to adopt a standardized approach, the next step is effective implementation. It’s not enough to simply have a visual welding inspection report template; your team needs to understand how to use it consistently and to its fullest potential. Start by customizing the template to perfectly align with your company’s specific operations, the industry codes you adhere to, and the typical projects you undertake. While a generic template is a good starting point, tailoring it with your unique project types, material specifications, and quality thresholds will make it far more effective and user-friendly for your inspectors.

Training is absolutely critical. Gather your inspection team and walk them through every section of the new visual welding inspection report template. Explain the importance of each field, define terms consistently, and conduct practical exercises to ensure everyone is on the same page regarding acceptance criteria and defect identification. Discuss the nuances of documentation, such as the level of detail required for defect descriptions and how to clearly mark repair areas. This unified understanding is what transforms a simple form into a powerful quality assurance tool.

Beyond initial implementation, regularly review and refine your template. As projects evolve, new technologies emerge, or industry standards are updated, your reporting tools should adapt. Encourage feedback from your inspectors – they are on the front lines and will have valuable insights into what works well and what could be improved. Consider digitizing the process as well; many modern solutions offer mobile applications that allow inspectors to complete reports on-site, include photos directly, and upload data instantly to a central database, significantly streamlining workflows and enhancing data integrity.

- Train your entire inspection team thoroughly on the template’s use.

- Regularly review and update the template based on feedback and evolving standards.

- Consider digital solutions for improved efficiency and data management.

- Maintain a centralized, organized archive of all completed reports for easy access and auditability.

Embracing a systematic approach to visual welding inspections, anchored by a comprehensive template, elevates the entire quality control process. It transforms subjective observations into objective, auditable data, ensuring every weld is scrutinized against consistent standards. This commitment to detailed documentation not only safeguards the structural integrity of your projects but also reinforces your organization’s reputation for excellence and reliability.

By streamlining reporting, improving communication, and providing a clear historical record, you empower your teams to work more efficiently, minimize errors, and deliver superior results. Investing in a robust reporting framework is an investment in quality, safety, and ultimately, the long-term success of your endeavors in the demanding world of fabrication and construction.